After finding the SEPT product you want to

purchase, click on BUY and the system will transfer

you to the NORMADOC store which provides the fulfillment process for SEPT.

Every checklist is available in PDF or word format. The latter format allows you to adapt the checklist to your business case and/or a media of your choice such as a web-based excel worksheet. This enables you to demonstrate compliance with the standard in a manner that is most efficient for you.

Every checklist comes with four hours of free consultation. SEPT will answer any question concerning the standard or checklist for 60 days after purchase.

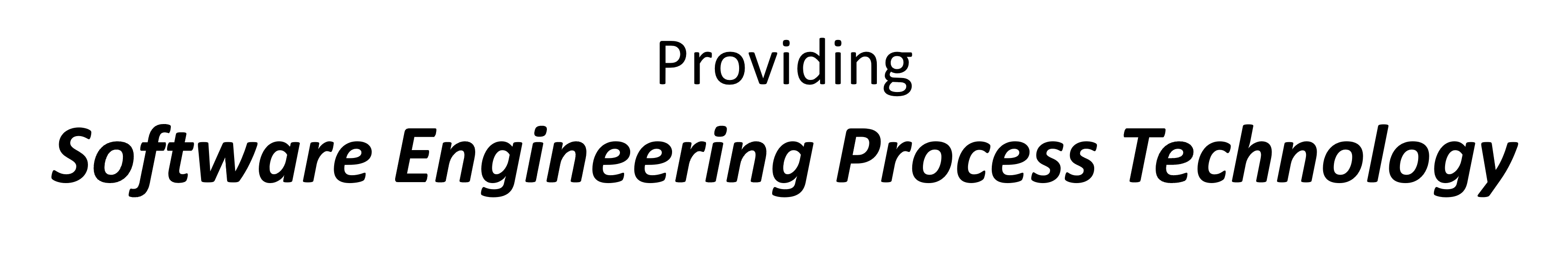

Checklist for - ISO/IEC 15288:2015-Systems and software engineering-System life cycle processes

Authors: Andy Coster and Stan Magee Pages: 448

In tabular form, this checklist defines by each clause and sub-clause of ISO/IEC standard 15288, what is required in the way of physical artifacts that demonstrates the standard has been followed. The types of artifacts listed in the checklist are procedures, plans, records, documents, audits and reviews.

When building a large complex system with many sub-systems such as an airplane, oil tanker, or setting up a new type of medical delivery system, it is a daunting task with high risk. Until 1995 there was no recognized ‘Best of Practice” standard that the world could agree on for building a large complex system. Then ISO developed the first standard (Best of practice) for System Engineering of large complex systems, which was ISO/IEC 15288. It initially defined about 600 artifacts to be produced in the development of a large system.

By 2015, the world was able to collect more and more “lessons

learned” from many large projects that failed, or had

massive cost, or schedule overruns. With this new data 15288

grew in size, to over 1050 artifacts. If an organization does

not have a clear picture of what artifacts are

required in the life cycle of such a system it is easy to miss

an important process step. This is why a checklist like the

SEPT checklist for 15288 is so important.

In total, there are over 1050 artifacts included in the SEPT 15288 checklist of which over 700 are “Required”.

|

Checklist for - ISO/IEC/IEEE 12207:2017, Software Life Cycle Processes

Authors: Andy Coster and Stan Magee Pages: 395

ISO/IEC 12207:2017 "System and Software Engineering -

Software Life Cycle Processes" is often confusing and

laborious. This is because directions contained in the

standard can seem unclear or ambiguous therefore the experts

at SEPT have produced a checklist. This checklist was prepared

by analyzing each clause in ISO/IEC 12207 for key words

that signify a required policy, procedure, plan, record,

document, audit, or review. The resulting checklist then

provides an easy-to-use categorized list of physical

evidence against which you can audit your work products

to help insure conformance with ISO/IEC 12207.

To better understand this model a user of this product

should understand SEPT definition of an auditor.

An auditor can be your boss, an inside auditor or an

outside auditor such as the FDA, DoD or a prime

contractor for your product. The checklist will give

the auditor and you a common reference point in the

standard (Clause number) that becomes the index point

for physical evidence. If a standard calls out

physical evidence more than once, such as a "training

plan" it is always index to the first clause that

reference the training plan This method will allow you

to organize your physical evidence in a systematic

manner for presentation to the auditor. This simple

checklist allows you to bring the document down to

simple terms that a professional lay person can

understand (policy, procedure, plans, records,

documents, audits and reviews).

The checklist will allow the organization to

divide the compliance activity into manageable

work packages such as procedures, plans, documents

etc.

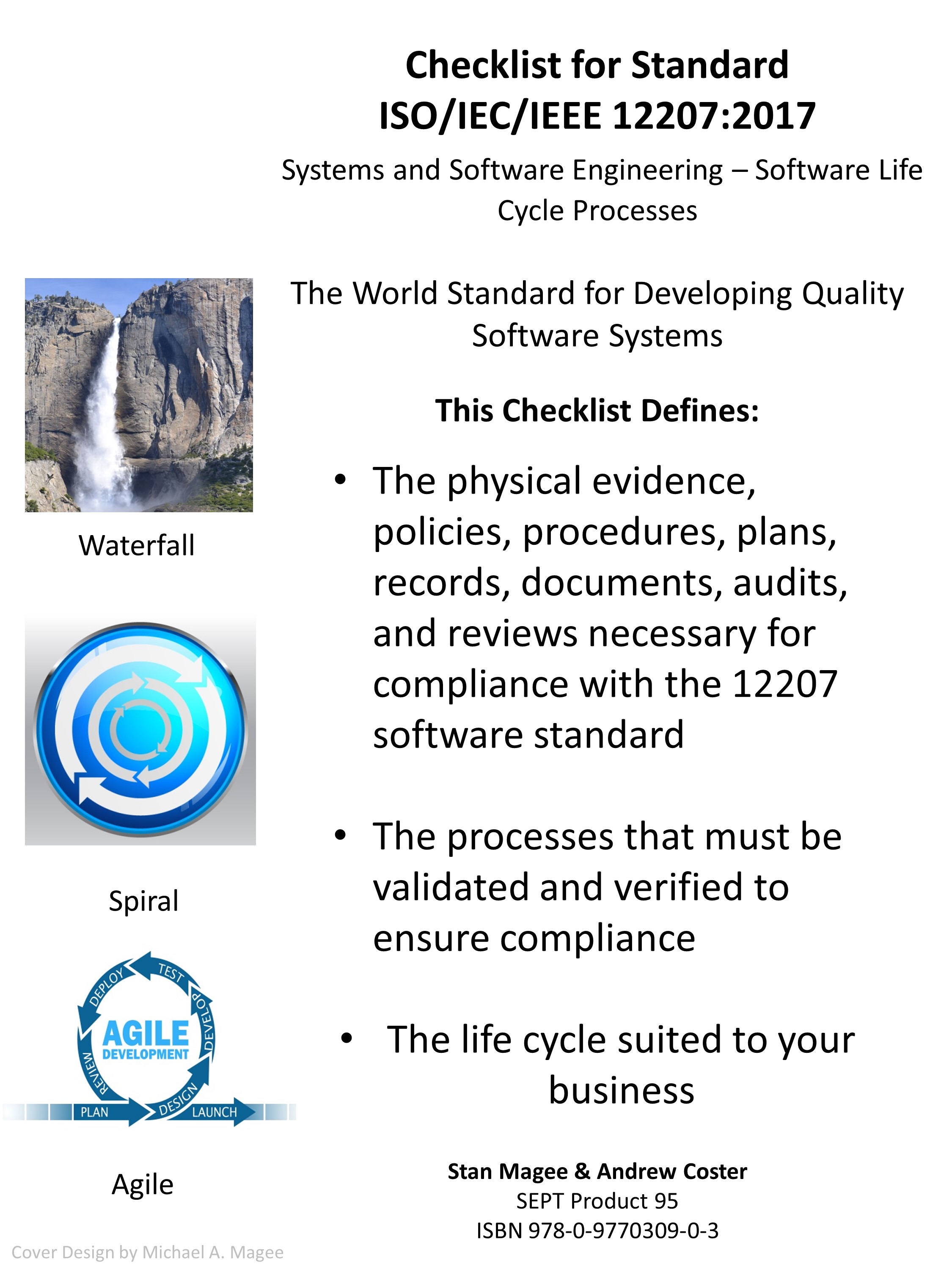

Checklist for - ISO/IEC/IEEE 42010:2011 Systems and Software Engineering —Architecture Description

Authors: Andy Coster and Stan Magee Pages: 41

The process of defining what is necessary for compliance

with a process standard such as ISO/IEC/IEEE 42010:2011

is often confusing and laborious because the directions

contained in the standards are unclear or ambiguous. To

aid in determining what is actually required by the

document in the way of physical evidence of compliance,

the experts at SEPT have produced this checklist. This

checklist is constructed around a classification scheme

of physical evidence comprised of policies, procedures,

plans, records, documents, audits, and reviews. There

must be an accompanying record of some type when an

audit or review has been accomplished. This record would

define the findings of the review or audit and any

corrective action to be taken. For the sake of brevity

this checklist does not call out a separate record for

each review or audit. All procedures should be reviewed

but the checklist does not call out a review for each

procedure, unless the standard calls out the procedure

review.

In this checklist, manuals, reports, scripts and specifications

are included in the document category. When the subject

standard references another standard for physical evidence,

the checklist does not call out the full requirements of

the referenced standard, only the expected physical evidence

that should be available.

The checklist clarifies what is required for compliance

through a product evidence list that will assist any

organization in meeting the requirements of this standard.

Use of the checklist will save time and money, and may aid

in meeting certain governmental requirements. This is an

aid that will pay dividends. A quality product at a

reasonable price!